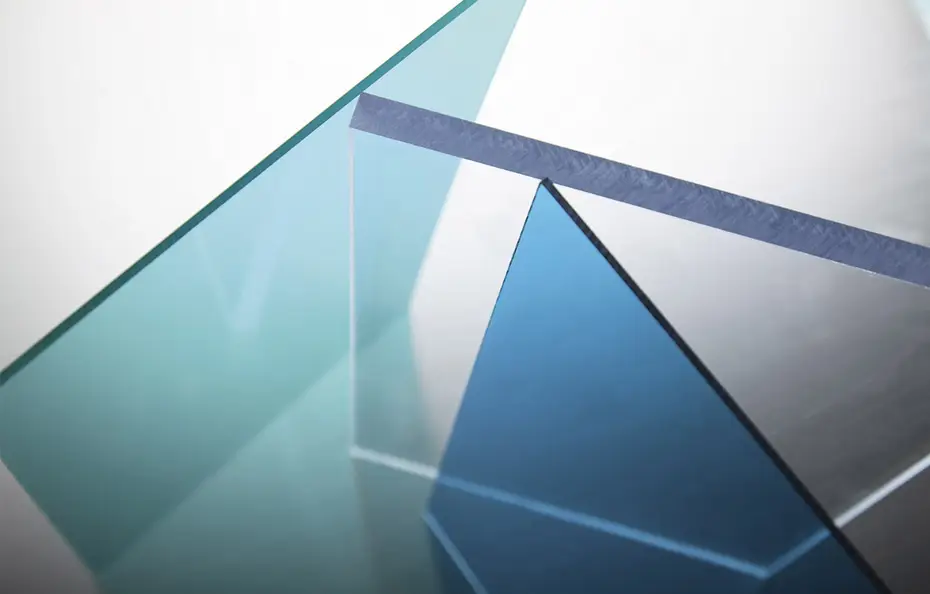

Polycarbonate Solid Sheets

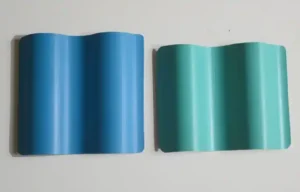

Explore high-performance polycarbonate solid sheets that combine exceptional impact resistance, optical clarity, and unmatched durability. Perfect for residential, commercial, and industrial applications across Pakistan.

Brands:

- Lexan® from SABIC-Europe

- Cornerstone® from Taiwan

- Sunshield® from Korea

Product Description

Key Features of Polycarbonate Solid Sheets

Exceptional Impact Resistance

- With impact strength 250 times greater than glass, polycarbonate solid sheets are virtually unbreakable, ensuring safety in high-risk areas like security glazing and protective barriers.

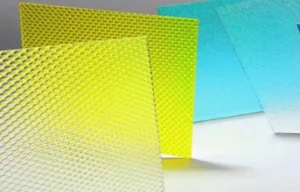

Superior Optical Clarity

- These sheets allow up to 92% light transmission, offering crystal-clear visibility. Perfect for applications such as skylights, greenhouses, and architectural glazing.

UV Protection and Weather Resistance

- Equipped with a co-extruded UV-resistant layer, polycarbonate sheets are protected from yellowing and degradation, making them suitable for long-term outdoor use in Karachi’s intense sun or Pakistan’s diverse climates.

Fire Resistance

- Achieving a B1 or Class 1 fire rating, polycarbonate sheets are self-extinguishing, adding a layer of safety to residential and industrial spaces.

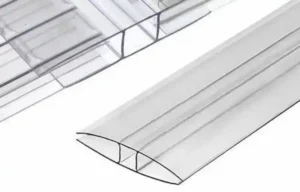

Easy Fabrication and Installation

- Lightweight and easy to handle, polycarbonate solid sheets can be cut, drilled, and shaped using standard tools, offering flexibility for customized projects.

Why Choose Polycarbonate Solid Sheets?

Polycarbonate sheets offer a versatile, lightweight, and durable solution for various roofing and construction needs. With excellent thermal insulation, UV protection, and fire resistance, these sheets are ideal for projects requiring strength and reliability.

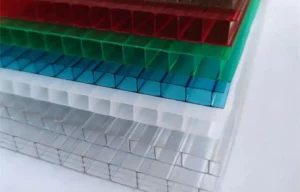

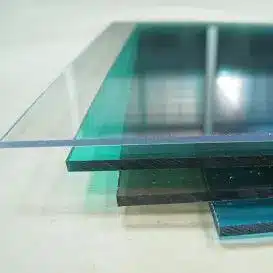

Technical Specifications:

| Property | Value |

|---|---|

| Size | 4' x 65' roll/ 4'x8' Sheet |

| Thickness | 2mm, 3mm, 4mm, 5mm, 6mm, 8mm |

| Availability | In pieces (of any required length) as well as complete roll |

| Light Transmission | Up to 92% (clear sheets) |

| Impact Strength | 250 times stronger than glass |

| Temperature Resistance | -40°C to 120°C |

| UV Protection | Co-extruded UV protective layer |

Polycarbonate vs. Fiber – A Clear Choice:

| Property | Polycarbonate | Fiber |

|---|---|---|

| Impact Resistance | Excellent | Good |

| Weather Resistance | Excellent | Poor |

| Temperature Resistance | Up to 120°C | Below 100°C |

| Light Transmission | Up to 89% | Up to 80% |

| Fire Spread | Self-Extinguishing | Flammable |

| Thickness | Uniform | Varying |

| Maintenance | Easy | Difficult* |

| TAC Approval (% of Total Roof Area) | 5% | Only 2% |

Applications of Polycarbonate Solid Sheets

Polycarbonate solid sheets are versatile and ideal for a range of uses, including:

- Security glazing for banks and embassies.

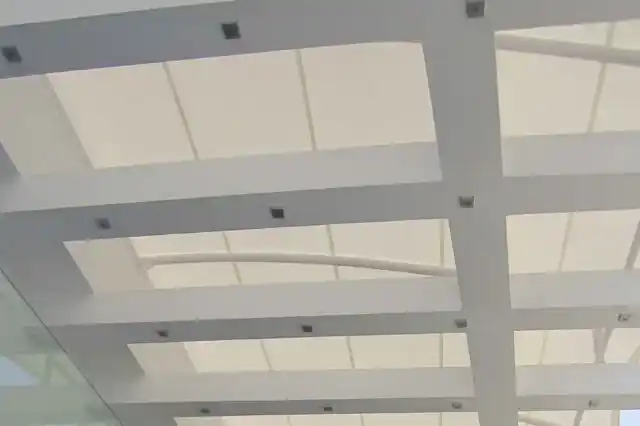

- Skylights and architectural glazing.

- Protective sports equipment.

- Greenhouses and conservatories.

- Noise reduction barriers in urban areas.

- Industrial equipment covers and safety shields.

Related Products:

Explore our other high-quality offerings, including:

Get Your Free Quote Today!

Contact Four M Enterprises for top-quality polycarbonate solid sheets tailored to your construction needs in Karachi and across Pakistan. Let us help you build stronger, safer, and more sustainable spaces.